DEDUSTING SYSTEMS

Particle removal technologies, commonly referred to as dust collection, involve the retention and/or reduction of coarse and fine particles in a gas path includes. The emission of particulate pollutants into the atmosphere from industrial and other sources has economic consequences as well as serious

health problems creates. Particles can have different chemical compositions depending on their origin.

Jet Pulse Bag Filters

Jet Pulse Bag Filters produced by Purifica A.Ş. together with Alfer are intensively used to clean industrial process gases.

is used.

These filters are bags, compressed air system, air lock, conveyor member, It consists of automatic control system and fan.

Purifica Inc. according to the needs of the customers;

-It can be used as modular and cyclonic filter.

- It can design its filters online or offline according to the cleaning method.

- It can manufacture its filters as stainless steel or wear-resistant steel.

- Dust and gases to be filtered; considering the criteria such as physical and chemical properties, density, working environment temperature, humidity.

bag selection.

- It uses galvanized or stainless steel wire mesh and venturi in the desired size, diameter and length, optionally segmented and suitable for the area of

use, and selects the most suitable wire by determining the number of wires, diameter and length needed according to the characteristics of the system.

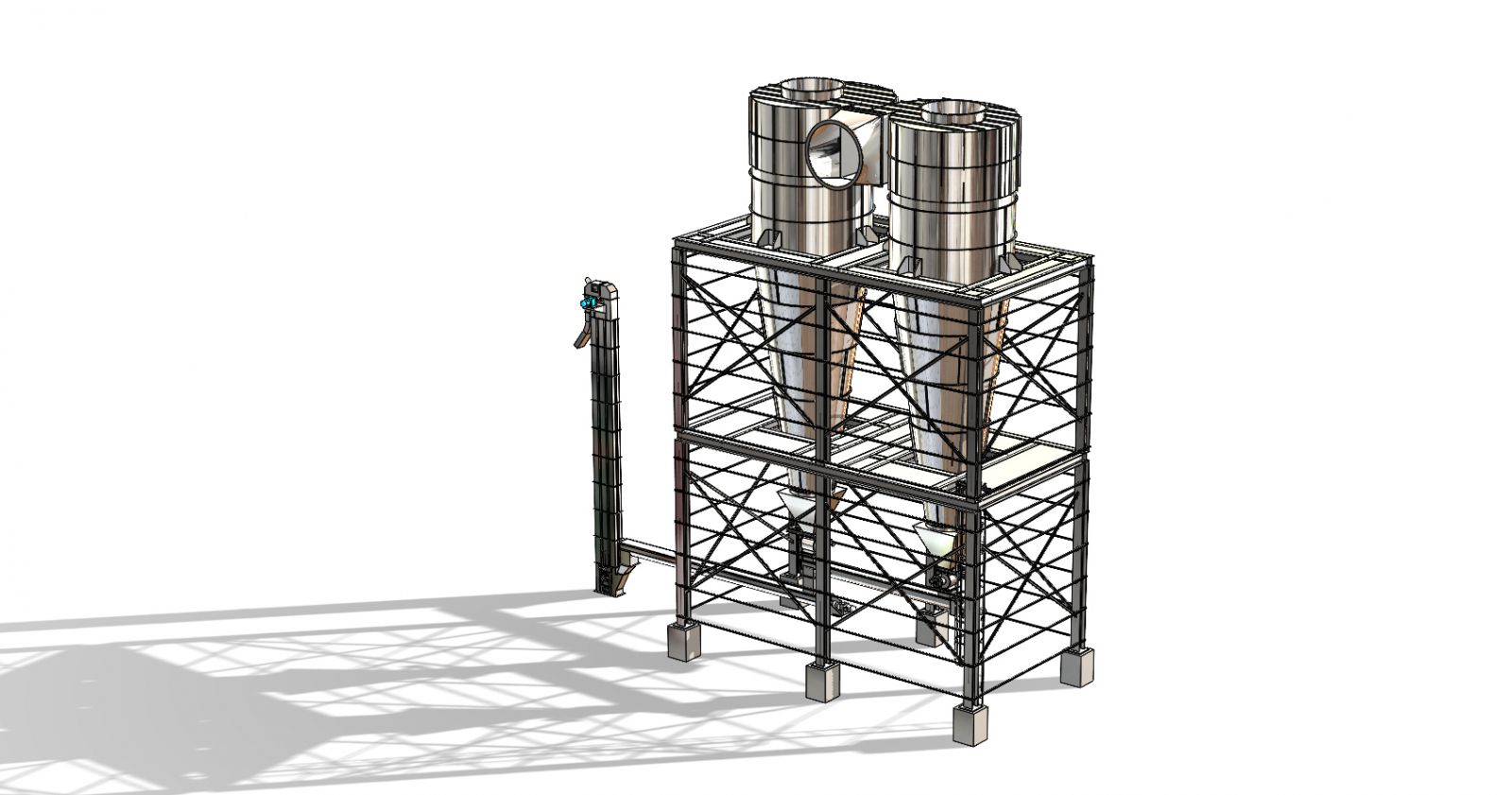

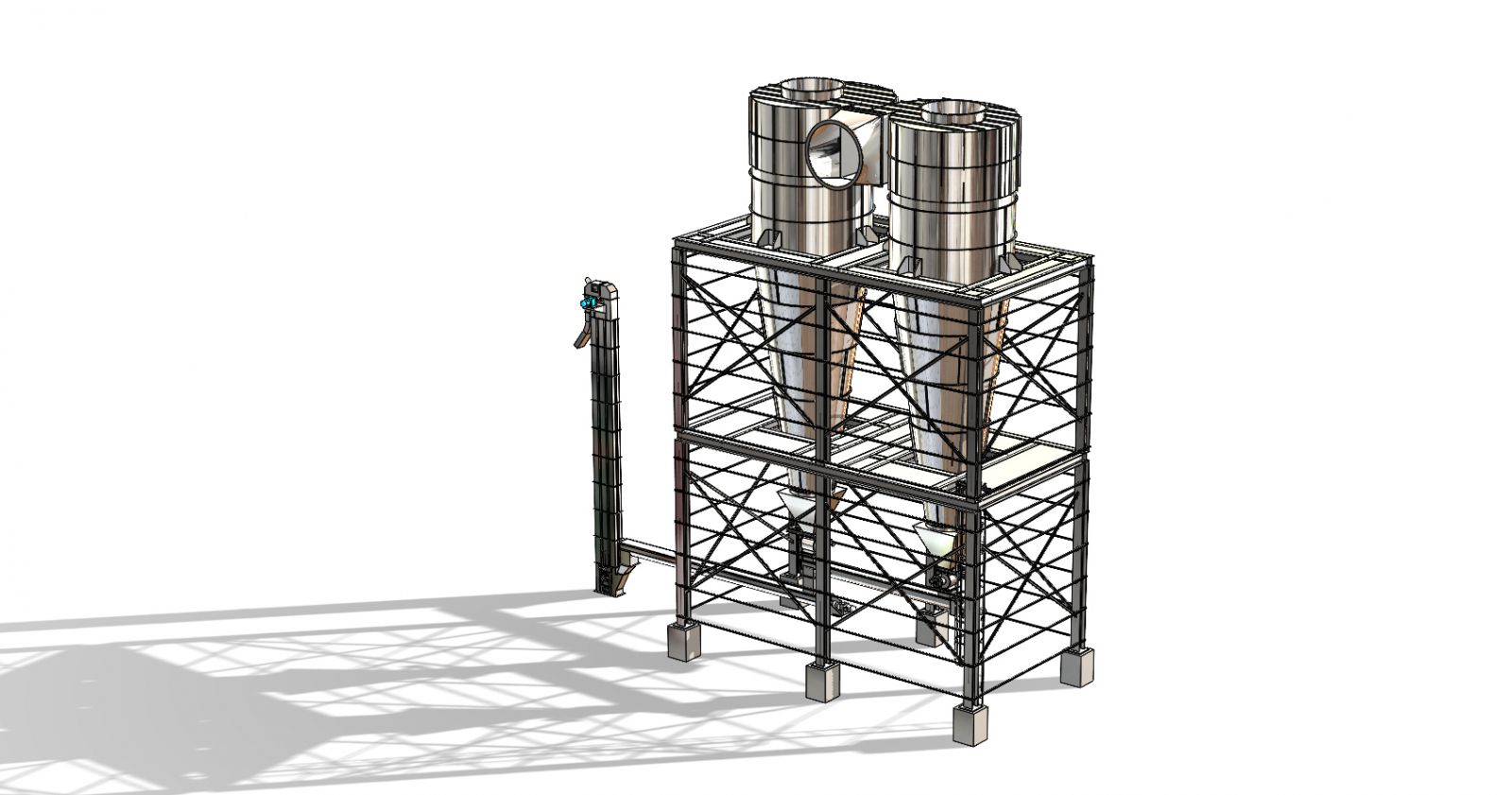

Cyclone Dust Collectors

Cyclone dust collectors are used as a pre-separator in industrial facilities to reduce the dust load on the filter, to keep the coarse particles before the filter is used. In this way, bag filters work more efficiently.

Necessary parameters for the selection of the appropriate cyclone;

- Flow rate and temperature of the carrier gas

- Particle size analysis of the material to be collected, dust distribution

- Specific gravity of the material to be collected

- Desired dust load at the cyclone outlet

- Information such as the targeted collection efficiency, the ratio of the material held in the cyclone to the material entering the cyclone. Alfer designs and manufactures cyclones using all these design inputs.

FANLAR

Particle removal technologies, commonly referred to as dust collection, involve the retention and/or reduction of coarse and fine particles in a gas path. includes. The emission of particulate pollutants into the atmosphere from industrial and other sources has economic consequences as well as serious health problems. creates. Particles can have different chemical compositions depending on their origin.

Particle removal technologies, commonly referred to as dust collection, involve the retention and/or reduction of coarse and fine particles in a gas path. includes. The emission of particulate pollutants into the atmosphere from industrial and other sources has economic consequences as well as serious health problems. creates. Particles can have different chemical compositions depending on their origin.